If you own a warehouse, factory, or another type of large industrial property, there’s a good chance you have a mezzanine on the premises. If so, it’s essential that your industrial stairs are wide enough to meet your needs while also being OSHA-compliant and in line with your local building code.

Industrial stairs that aren’t up to code can be serious safety hazards, and could make you liable to massive fines. You may even have to shut down your business until you fix any issues and get your stairs up to code!

If you want to know the minimum width and height requirements for industrial stairs, you’ve come to the right place. This article will explain everything you need to know about code requirements for industrial stairs, as well as how to ensure you have safe, secure, and effective stairs for your business.

Right off the bat, it’s important to note that industrial stairs are not the same things as commercial stairs. An industrial stair refers to any type of stairway that gets installed in a manufacturing facility, warehouse, or similar facility.

Commercial stairs, on the other hand, can refer to stairways in business complexes, shopping centers, and other types of commercial entities that are open to the public.

It’s important to make this distinction because different codes apply to public spaces, which means that commercial stairs are often more expensive than industrial stairs because they must be built up to a stricter code.

In general, an industrial stair will not be open to the public, unlike a commercial stair. As such, they have different code requirements than commercial stairs and are designed and constructed to meet those needs.

Now that you have a better idea of what industrial stairs are and how they’re different from commercial stairs, let’s examine their code requirements.

The Occupational and Safety and Health Administration, OSHA, is the gold standard when it comes to building and safety regulations.

According to their website, industrial stairs must have 22″ between vertical barriers. In other words, there must be at least a 22″ gap on your stairway for people to pass through.

While OSHA has minimum width requirements for industrial stairs, they don’t have any limits on maximum width for the stairs themselves.

They do, however, specify that you can have a maximum of 88″ between two handrails. So, while you can make your stairway as wide as you want, you can never go more than 88″ without having a handrail in place.

Along with OSHA, your industrial stairs may also need to be compliant with IBC standards. IBC stands for International Building Code, and its sole purpose is to ensure that buildings and structures are as safe as possible.

This is slightly different from OSHA, which focuses more on worker safety rather than on physical buildings and code requirements.

The IBC tends to be stricter than OSHA when it comes to code requirements for industrial properties. Therefore, if you have industrial stairs, you may have to be compliant with the IBC as well as OSHA when it comes to minimum width requirements.

According to their website, IBC 2024 requires a minimum industrial stair width of at least 44″ unless the occupancy load of the story is less than 50 people at a time, in which case the minimum width requirement is 36″.

It’s important to note that the minimum width can be larger based on the occupancy load (or how many people will use this stair). The IBC says you need at least 0.3 inches of stairway width per person. If you have automatic sprinklers and a fire alarm they only require 0.2 inches of width per person.

For example, if you anticipate that 250 people may need access to your stairway, you must have a minimum width of 75 inches, or 50 inches if you have automatic sprinklers and an alarm system.

Here are a few additional industrial stair requirements to consider:

Since IBC is an international standard, its code requirements remain consistent across states. However, while there is a federal OSHA code, state codes may vary by location, so you should verify the minimum width requirements for industrial stairs specific to your state, county, and city. Additionally, you must check your municipality codes, as they can adopt different codes than your state. For instance, the city of Chicago might have codes that differ from the rest of the state.

In addition to OSHA and the IBC, the IRC (International Residential Code) also has code requirements when it comes to stairways. However, the IRC only applies to residential stairs, so you don’t have to worry about making your industrial stairs compliant with their regulations.

Along with ensuring your industrial stairs are wide enough, you also need to meet OSHA and the IBC’s slope requirements. According to OSHA, your stairs can have 30 to 50 degrees of slope.

IBC states you must have at least 11″ of run along with a maximum of 7″ of rise. While that’s confusing to people outside of the stair industry, it basically ensures your stairs will have a slope of 20 to 33 degrees.

Once again, it’s important to note the difference between commercial, residential, and industrial stairs. All industrial stairs must be OSHA compliant, and, in some cases, IBC-compliant as well.

Residential stairs, on the other hand, must be compliant with only IRC standards, while commercial stairs must meet a different set of IBC standards than industrial stairs.

Code enforcement is ultimately up to your local inspector, as they’re the ones who will interpret which codes apply to your stairs. They use a great deal of discretion and have some leeway in how strictly they enforce IBC and OSHA rules and regulations.

Therefore, it pays off to have a positive relationship with your local building inspector!

For example, there was an instance where PWI installed an industrial stairway and we made the rails slightly lower than the typical code requirement. They were built according to an outdated version of OSHA code, rather than the current updated one. Historically, this hadn’t been an issue, as most building inspectors still considered the stairs and railing safe for use.

Unfortunately, the building inspector in this instance decided to enforce the code to the letter of the law, and we were required to modify the rails in question.

Because it was a new construction project, the business in question wasn’t allowed to start working until the issue was fixed and the inspector signed off on our work.

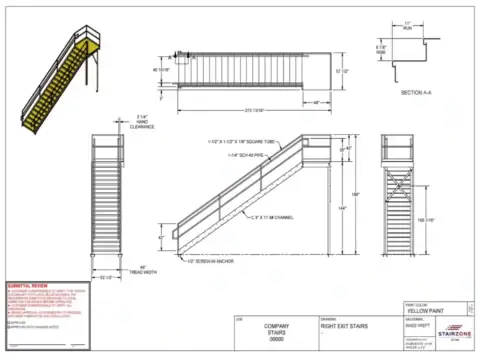

As such, it’s important to build your industrial stairs so that they’re code compliant, even if you think it won’t be a problem. To that end, we always recommend that you check with your local building inspector before we approve your drawings, as it will help get your project off to a smooth start.

Along with minimum width requirements, OSHA and the IBC also have riser height and tread depth requirements for industrial stairs. Riser height refers to how tall a step is, while depth refers to how deep it is, also referred to as “nose to nose.”

The IBC requires your riser height to be between 4″ and 7″, while OSHA has a maximum riser height of 9 ½”.

Additionally, the IBC’s minimum tread depth for industrial stairs is 11″, while OSHA’s is 9 ½”. When you combine the slope requirements with the depth and riser requirements, you get the perfect industrial stairway.

If you aren’t confused enough already when it comes to width requirements for industrial stairs, there are also different requirements for different types of stairs. Here’s a quick rundown of the minimum width requirements for different types of industrial stairs:

Additionally, other types of stairs, including L-shaped (90 degree), switchback (180 degree), and crossover stairs (scissor), are hybrid systems that combine different types of stairways. As such, they need to comply with whatever the standard is for their base type of stair.

It’s important to note that OSHA and the IBC may have different names for different types of stairs. OSHA’s spiral stairs, for instance, are referred to as winder stairs in the IBC handbook.

Additionally, the IBC doesn’t even recognize alternating tread-type or ship stairs as a type of stair, while they’re specifically referenced in OSHA’s handbook. This is because those types of stairs are specifically designed for work environments and require training to use safely.

Both OSHA and IBC require guarding to be 42″ tall, and handrail to be installed at 34″ to 36″.

The IBC also requires that you have no more than a 4″ gap in your railing in a stairway in public access settings, while they allow up to 18″ rail gaps in factory settings.

OSHA requires that doors opening onto a landing don’t reduce the usable depth of the landing to less than 22”. Additionally, mid-landings must be at least 30″ deep. However, this only applies in situations where the door opens onto the landing. Additionally, there are no minimum-depth requirements for top landings.

If you have stair-building or construction experience and you’d like to build your own stairs, there’s no rule saying you can’t do that. However, it’s essential that you comply with the same building codes and regulations that a professional stair-builder would.

For instance, if you’re building a stairway at your home or shop for personal use, you need to comply with IRC standards for residential stairways. However, if you’re building stairs for a home office or business, you must comply with IBC and OSHA standards.

If you build a stairway to the wrong standards and need to have it inspected, you will likely fail your inspection. When that happens, the inspector will deny you occupancy to your building until the issues are fixed and you rebuild your stairs according to the proper standards.

The most important thing to remember when building industrial stairs is that you should always, always, always consult your local building inspector before you begin construction.

The inspector ultimately knows which building codes apply to you and how strictly they will enforce them. Additionally, they alone have the power to pass or fail your inspection, which will determine how quickly you can occupy your building.

As you can see, there’s a lot to consider when it comes to industrial stairs. Between OSHA, IBC, IRC, building inspectors, and the different rules that each organization has, it’s tough to keep up with the proper way to build industrial stairs.

Therefore, in addition to always consulting with your local building inspector, we recommend turning to PWI to ensure your industrial stairs are built safely, securely, and up to code.

If you want a compliant stair quote and drawings in as little as 10 minutes go to our stair builder. It is 100% free to use!

Many buildings and residential homes require stairs to get from one level to another. Today, general Many buildings and residential homes require stairs to get from one level to another. Today, general contractors and homeowners have many options when it comes to designing a staircase for their area. There are a variety of stair materials to choose from, but the most common are: wood, steel, and precast concrete.

The choice of the material you will use to build the stairs may be influenced by several factors, including:

While there are several options to choose from, the most common materials used are wood and steel.

Steel and wood are two prominent stair materials that are frequently used. Determining which one is best can be tough, because each has its own strengths and weaknesses.

Here is a rundown of each material, and its pros and cons.

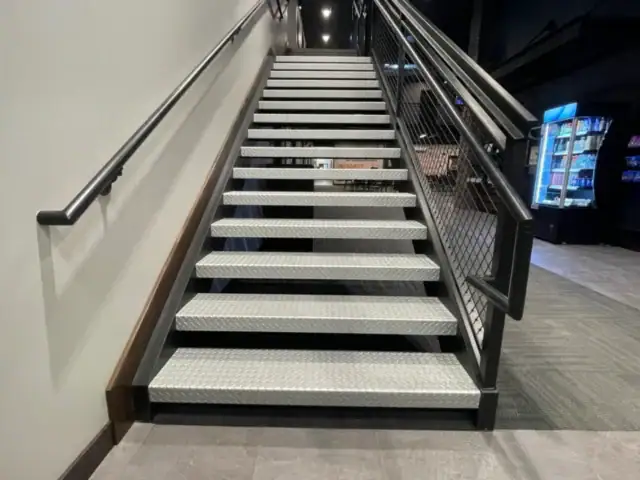

Steel stairs have gained popularity recently, especially in homes, offices, and business premises. They are a replacement for concrete stairs which are known to be expensive and difficult to construct.

Most people prefer metal because of its flexibility and durability over other materials. You can fabricate them into different shapes, styles, and choose your own paint colors.

Here are the pros and cons of a steel stair:

Wood stairs have also been around for quite some time. Wooden products add a classic element to facilities and homes, as well as a touch of style and richness.

While it won’t last as long as steel, it performs exceptionally well when treated to delay the natural degradation process that results in its wearing and rotting away. When wood stairs are painted or polished to a gleaming look, it can last longer.

But environmental concerns across the globe mean that wood will become rare, as agencies work to limit the cutting down of trees. Trees may become more expensive to use, and people may have to look for other alternatives.

Here are the pros and cons of wood stairs:

While there are certain benefits of wood stairs, you may want to choose steel stairs because of their numerous benefits over their wooden counterparts. Steel is much stronger and long-lasting compared to wood. It is also much easier and cheaper to install than wood stairs.

It is certainly possible to combine steel and wood stairs into one. A popular way this is done is by creating the frame and railings of the stair in metal, and then using wood treads. This creates a more custom look and gives you the durability of steel stairs.

Stair Zone is an easy-to-use online stair builder that grants you with instant pricing and fast drawings. Our 45 years of experience and professionalism go into the production of every steel stair to satisfy all of our clients. Use our stair builder to get instant pricing or if you require something more custom, request a free quote.

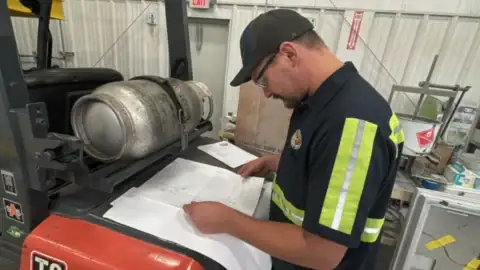

Recently, we partnered with an ambulance manufacturer in Elkhart to tackle a challenge in their storage area in order to improve safety and efficiency.

The customer had been using mobile “roll-away” stairs to access their upper storage area. While functional, this setup posed significant challenges:

The customer needed a solution that not only addressed these issues but also optimized the workflow for their team.

After assessing the site and understanding the customer’s needs, our team designed and installed a custom system that checks all the boxes:

By combining these three different products, we delivered a comprehensive solution that met both safety and operational requirements.

The new setup has significantly improved the customer’s operations. Here’s how:

This project is a great example of how custom-engineered solutions can solve complex challenges. By focusing on the customer’s unique needs, we were able to deliver a safer, more efficient workspace that supports their day-to-day operations.

At PWI, we’re committed to creating solutions that improve your workspace. Whether it’s a new crane system, mezzanine, fall protection system, or customized stair design, we’re here to help you take your workspace to the next level.

Ready to improve your facility’s safety and efficiency? Contact us today and get a free quote for your next project!

Stair Zone was a pleasure to work with. Their process from concept to design and fabrication to delivery worked great. Communications regarding fabrication and delivery was excellent as well.

We ordered some custom built stairs for a steel mill expansion. Stair Zone & Kaleb made the process extremely simple - even with all our changes in design.

Purchased one set of outdoor stairs for our warehouse. Great value with excellent precision and fabrication quality. The quality led us to replace our other set of stairs instead of repairing them. Highly recommended for anyone needing prefab platforms or stairs.